Antifouling is designed to protect the hulls of boats from the accumulation of algae and small marine organisms that settle on submerged parts. Beyond aesthetic reasons, antifouling is periodically applied to boats because the long-term buildup of flora and fauna reduces the boat’s performance and can damage the hull. However, there are many different types of this product on the market, and not all boat owners have the necessary knowledge to understand which is the best choice. In fact, antifouling should be selected based on the type of boat and how it is used, as well as the waters in which it sails or is moored. In any case, it’s beneficial for boat owners to have a basic understanding of hull preparation and protection, so they do not rely solely on shipyards. Therefore, we have prepared a comprehensive guide to antifouling for boats, with the help of Gianluca Sansonna from Lechler, which produces a wide range of marine coatings under the Stoppani brand.

Antifouling for boats: what it is and what it used for

Antifouling is a paint coating applied to the submerged part of boats (called the “hull”) to protect it from the settlement of fouling (a term used to describe crustaceans on the hull). “Without this protection, the fouling, by changing the profile and adding weight to the hull, would slow the boat down, increase fuel consumption, and, in some cases, seriously damage the hull”, explains Sansonna.

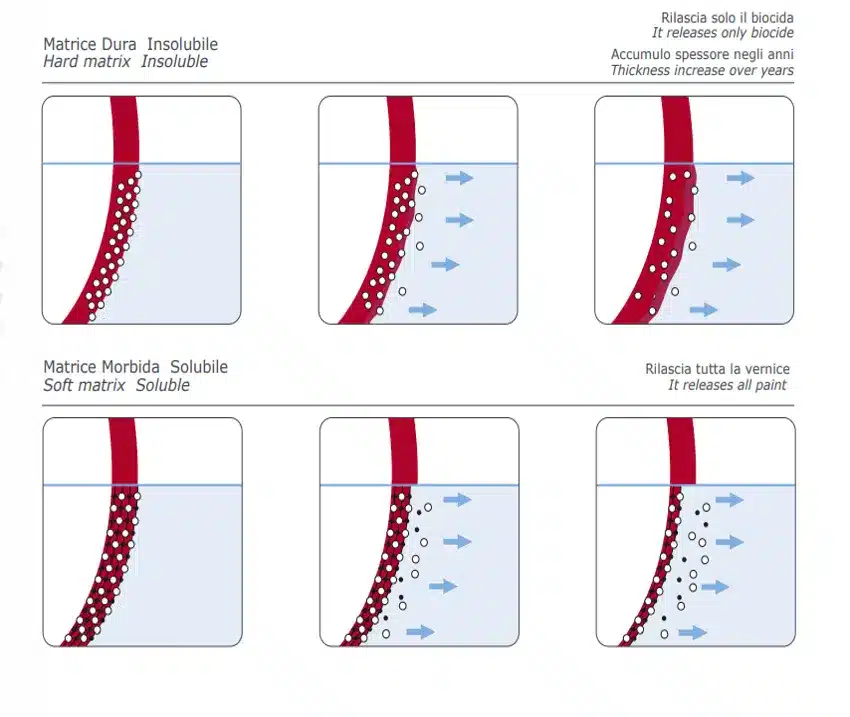

Like all paint products, antifoulings contain resins, solvents, pigments, and active ingredients (biocidal components). The latter prevent the formation of biological crusts on the hull. Based on the release mechanism of these components, antifoulings can essentially be grouped into two main categories:

Hard Matrix Antifouling: This type releases active ingredients slowly over time, independently of the boat’s movement. It is suitable for both fast boats and those with moderate speed.

Soft Matrix Antifouling (commonly known as “self-polishing“): This type releases the paint (not just the biocides) by contact with water during navigation, wearing off with use and thus avoiding the buildup of thickness. By increasing the initial thickness of the paint, the protection time of the antifouling is extended.

The differences in functioning between hard matrix antifouling and self-polishing antifouling are illustrated in the following image.

Recommendations for use

Sansonna suggests some precautions for applying antifouling on boat hulls. Here are his recommendations:

Never apply a hard matrix antifouling over a previously applied self-polishing antifouling.

In case of doubt about compatibility or with old antifoulings where compatibility is unknown, apply a coat of primer.

Mix the product well before application.

The application must follow the quantities indicated in the technical data sheet, as applying less than the recommended amount will compromise the duration of the antifouling protection.

Two coats of antifouling are always necessary, with a third reinforcing coat on high-wear areas.

Always adhere to the launching times indicated in the technical data sheet.

Choosing the right antifouling requires considering several factors such as the type of boat, speed, existing products, water quality, and environmental regulations.

“The boat’s hull should never be left to age, especially if it’s an old wooden hull – emphasizes Sansonna – Therefore, antifouling should be applied to the hull at least every two years. Additionally, there are two situations where it is better to return to the original primer rather than applying a new coat over the existing layer. These situations are when we do not know which antifouling has been previously applied to the hull and when we have a different matrix from the one we want to apply”.

Wood. “Wood continues to hold significant importance in the nautical environment. This is due to its historical tradition (vintage boats) and its natural elegance, which makes it practically irreplaceable in the furnishings and decks of high-end boats. In reality, wood also has a series of technological characteristics that make it an interesting material in the nautical environment. Wood can be considered a natural composite material, sourced from renewable resources, lightweight, economical, and easily workable. The main characteristic to consider when preparing to paint wood with antifouling is the moisture content, which must be below 15%”.

Steel. “Steel is the primary construction material for large vessels and superyachts due to its exceptional strength, ease of workability, and low cost. However, its high specific weight and poor resistance to corrosion are significant drawbacks. Carbon steel is used in shipbuilding, and during the construction phases, the material has no protective coating. In this unprotected state, bare metal quickly oxidizes, so it must be protected with an appropriate epoxy primer immediately after sandblasting”.