Let’s discover the most important technical aspects that a shipyard should consider when choosing a boat filler

Boats are primarily objects of pleasure, but often their owners are unaware of the complexity behind their construction. The latter is, in fact, a complex process of study, realization, and assembly of various components, both visible and invisible, which must harmonize with each other and achieve the highest possible level of comfort, performance, and aesthetics. In the latter aspect, one of the most important features is the hull color: the quality of the paint, the depth of color, and the glossy appearance are indeed the first characteristics that impress those approaching a yacht. In order to achieve a high-level result, entire teams of paint artisans must carry out meticulous preparation work for painting, and in this process, one of the most critical and demanding steps is surface leveling. Indee, it is often necessary to fill in the irregularities caused by the misalignment of panels during the construction of steel and aluminum boats or by the deformation of the panels during the post-curing phase of composite materials. For this task, paint applicators, after evaluating the correct measurements, create templates, using a specific boat filler for leveling. It is a highly filling spatula filler, and since this product becomes an integral part of the boat’s structure, it must possess high-level mechanical features that can withstand the test of time.

The following are the main technical characteristics that a reliable and resistant boat filler must have:

- Waterproofing: This is ensured by the epoxy resin used in the formulation of the boat filler, providing an exceptional water-resistant barrier;

- Adhesion: When a boat moves through water, significant forces are at play, making it essential for the filler to firmly adhere to the surface and maintain this adhesion over time;

- Flexibility: This allows the filler to withstand the forces and deformations experienced by a boat in water without breaking;

- Lightweight: This helps limit the weight of the boat, thus preserving its buoyancy and navigation capabilities. It’s a crucial aspect considered already during the design phase.

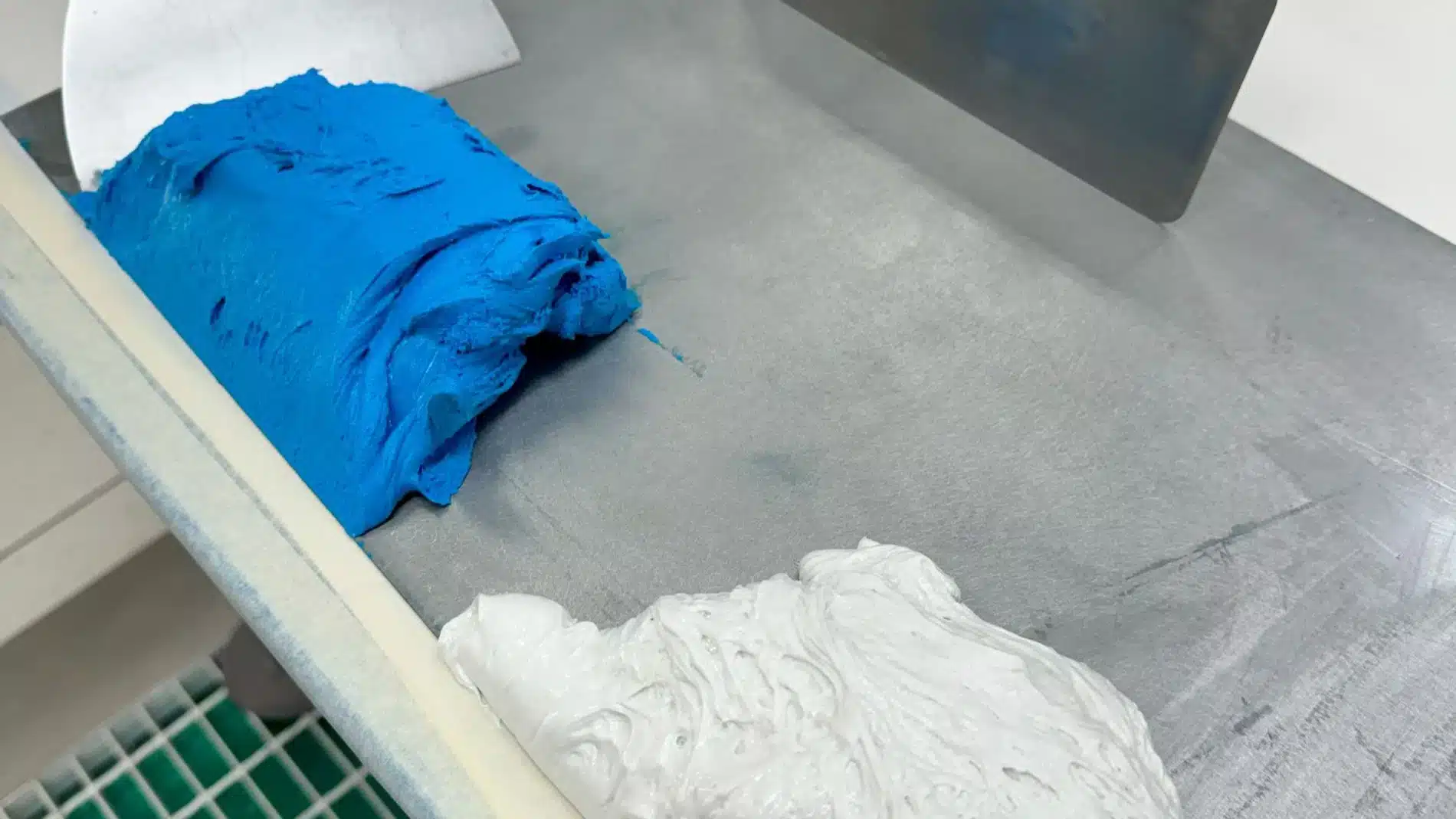

Plaster Six Boat Filler

Thanks to Plaster Six, sanding is much easier, and this is precisely what has made shipyards enthusiastic about this new Stoppani product. Moreover, Plaster Six can be used even at low temperatures; it can be applied to any type of surface, whether it be fiberglass, steel, aluminum, or wood; and it has very fast drying times, unlike other types of boat fillers: three more features highly appreciated by boat builders.

However, to achieve the best possible result, it’s important to apply and use the boat filler correctly. This topic will be addressed in an upcoming article.