Choosing boat propellers depends on various factors, including the type of boat, the engine, the intended use, and the owner’s travel preferences. It is a key element that determines the efficiency of the watercraft, and it is precisely for this reason that it is necessary to carefully evaluate a series of variables. Luca Radice, owner of Eliche Radice Spa and a true guru of boat propellers, explains how to make the right choice for this important marine accessory.

Boat Propellers: the best material

” First and foremost, the choice of material is crucial – Mr. Radice begins – The preferred materials for boat propellers are marine bronze alloys, which, in the case of our company, are divided into two types, both developed in-house and our intellectual property”. These are the two alloys:

- Otman alloy, made with a base of bronze and manganese, is preferable for slower boats, such as sailboats or workboats, due to cost considerations.

- Mibral alloy, composed of bronze and aluminum, is more suitable for propellers on high-performance and fast boats. It is also recommended for aluminum hulls as it does not pose issues related to galvanic corrosion.

Diameter and Pitch: two important factors

To choose the best boat propeller, it is necessary to understand the diameter and pitch of the model that suits your boat type. More specifically, the diameter of the propeller is a crucial factor for providing proper thrust to the boat, while the pitch (the theoretical distance covered by a propeller during one complete rotation) needs to be carefully balanced to achieve the desired performance for the boat owner.

“The correct correlation between the diameter and pitch of the propeller is determined through calculations, preferably supported by reports in a naval tank, in cavitation tunnels, or through specialized CFD software – explains Luca Radice – In this step, the most challenging part is not so much calculating the right propeller but understanding the correct performance of the boat. In the case of Eliche Radice, we have a program that provides us with performance and efficiency curves for the propeller based on the boat’s data and speed. This helps the customer choose the model that best suits their needs and is more efficient in terms of performance, noise, and fuel consumption”.

Boat Propellers: the correct number of blades

As all boating enthusiasts know, boat propellers can have a different number of blades. But how to determine the correct one? Mr. Radice explains: “Our computer software is capable of telling us the correct surface area the propeller should have according to the boat, but this surface can be distributed over a different number of blades. For example, if we need a one square meter propeller, we can divide it over three elephant ear-shaped blades or six slender blades. As a general rule, the narrower the blade, the less water it moves, resulting in less boat vibration and turbulence, which means greater comfort aboard. However, propeller efficiency is always achieved with the lowest possible number of blades. Therefore, it’s about finding the right compromise between performance and the owner’s needs. A sound decision in this regard should be the foundation before embarking on any design project”.

Reduction Ratio

Last but certainly not least, the engine’s reduction ratio is also crucial in choosing the right boat propeller. “After the horsepower, it is by far the most important aspect,” Radice concludes. “The first question we ask our customers when they seek consultation for a project is to provide us with a list of available reduction ratios. This allows us to suggest the most suitable boat propeller for optimal efficiency.

We often find ourselves advising some boat owners who wish to get a new propeller to first change the reduction gear, or else they might as well keep the propeller they already have. This is because, especially on slower boats with engines running up to 3600 RPM, they might have a 2:1 reduction ratio, meaning 1800 RPM for the propeller. However, it may turn out that the owner never goes up to 3600 RPM and always stops at 2000 RPM, so the boat doesn’t perform well because it has a propeller designed for 3600 RPM. With the same propeller, they can reach 7.5 knots at 3600 RPM and only 4.5 knots at 2000 RPM.

In these cases, the only possible solution is to have a reduction gear that brings the propeller to rotate between 1400 and 1500 RPM, where we have a larger diameter and greater efficiency, which can mean reaching one more knot. It may seem insignificant at first glance, but on long journeys, it makes a difference. Often, it’s not the propeller that doesn’t work well, but everything that comes before it.”

About Eliche Radice

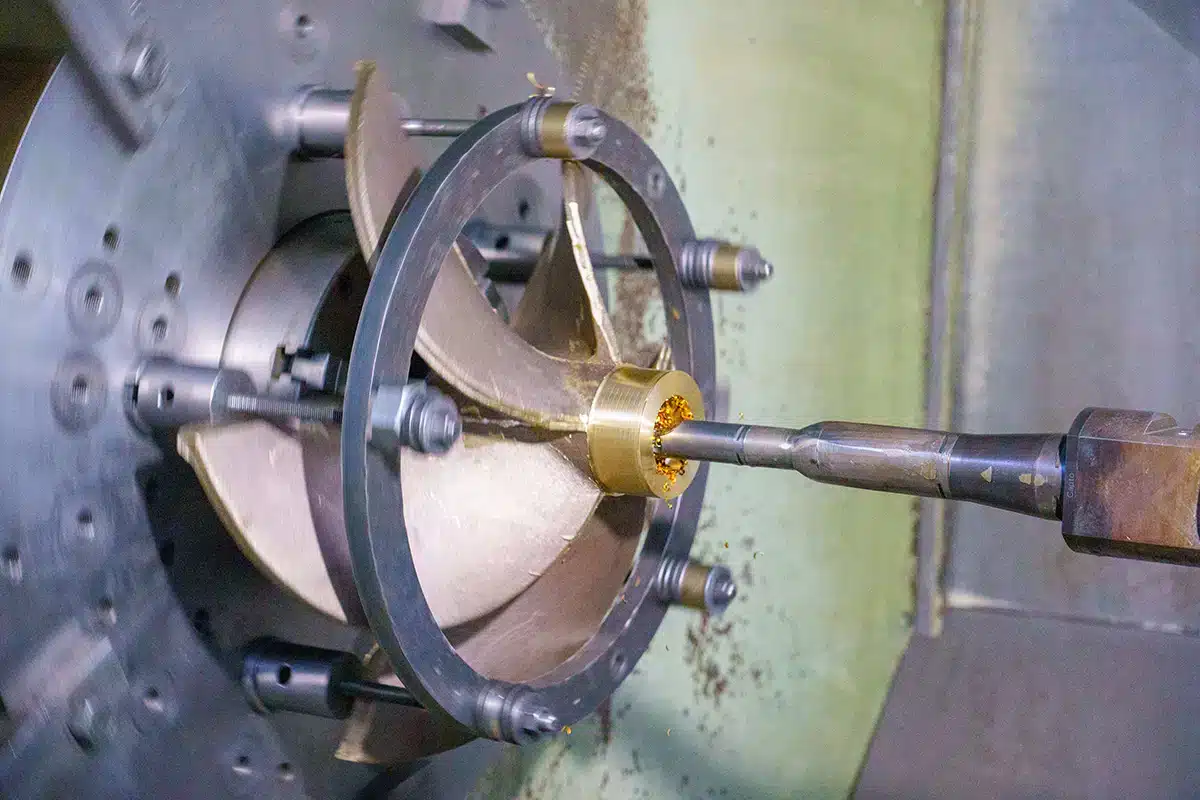

Eliche Radice is a prominent reference in the yachting industry. Founded in 1919, the company is still under the ownership of the Radice family, who have consistently dedicated themselves to innovation in the realm of boat propellers, working tirelessly to enhance the efficiency, performance, and design of these crucial marine components. With an entrepreneurial vision that exemplifies leadership, Eliche Radice has become a benchmark in the industry, offering innovative and high-quality solutions to customers worldwide. All production stages, from casting to modeling, are carried out in-house. This not only simplifies quality control processes but also enables precise management of deliveries and warehouse availability.

Today, Eliche Radice boasts a corporate facility spanning 50,000 square meters in its headquarters in Cinisello Balsamo, including 15,000 square meters of covered space and approximately 85 employees. In addition, the company has a commercial division in France.

The Eliche Radice product range encompasses not only boat propellers but also various components of the entire propulsion system, from the coupling flange to the gearbox, all the way to the rudder. Among Radice’s products are fixed-pitch tractor or propulsion propellers for directional systems, blades and hubs for variable-pitch propellers, propeller shafts and their supports, seals, fixed or directional nozzles, hydro-lubricated bushings, and rudders. For fixed or variable-pitch monobloc propellers, the maximum diameter of Radice products is 4 meters or 4 tons in weight, while for propeller shafts, the maximum length is 12 meters with a diameter of 250 millimeters.