There is a strip of the Po Valley, enclosed between the Oglio and the Serio Rivers, where passion for boats has been going on for over 50 years.

For in this area of northern Italy that is the province of Cremona, in a town which is home to a few hundreds of residents, 1956 marked the birth of Alpa (Azienda Lavorazioni Plastica e Affini), a company which quickly became one among the most important realities in the Italian boat industry and the manufacturer of thousands of boats, the most famous of which are probably the Alpa 9.50 and the Alpa 11.50. And, above all, this was the birthplace for generations of skilled craftsmen, boat-builders, laminators, carpenters and joiners who shaped a new high-profile specialized craftsmanship.

It’s a history that, through all the ups and downs, has never really stopped. Maybe through the net of canals marking this land like wrinkles, skills and knowledge have been maintained over time and have given birth to other realities in the world of craftsmanship and boat industry. Until 2012 when, in Salvirola, a few kilometres from Offanengo, was established Ice Yachts, a reality where industrial aspects, technologies and traditional craftsmanship merged together to give birth to a profoundly Italian reality with a large foreign market.

So, Ice Yachts was founded 5 years ago in the former facilities of another historic shipyard, CN Yacht 2000, from which it has inherited skilled workers now flanked by new workforce.

As the head of the business, Marco Malgara gathers experts coming from different working backgrounds who share the same passion for innovations and innovative materials.

In Ice Yachts sheds, a sort of electrifying mixture is immediately created. Malgara has a precise goal: to fuel and keep alive the competences of the past experience and transfer them in his vision of the future. Those sheds have been the construction site of boats designed by Vallicelli, Felci and Starkel Studio. Workers and technicians have built models of all sizes, from Lobster to Uldb yachts and the Grand Soleil 70.

This enormous know-how is now revitalized and spurred by an innovative vision resulting in new boats with a very strong personality.

“We made a precise choice- Ice Yachts Sole Administrator Marco Malgara explains – that is Italianity. Our in-house production is a value and a guarantee for anyone looking for something unique”.

Native of Milan, married and father of two children, Malgara is a businessman who landed in boat industry after a career spent in other professional sectors thanks to an innate passion for sailing and a great love for CN Yacht 2000 boats. ” I desired a boat built by that shipyard – he says while he takes us to the lamination department – so I decided to invest and take over the whole shipyard”.

So, 2012 marked the beginning of a new production characterized by high customization, large use of carbon, extreme care of all in-house production processes and a new designer: Umberto Felci.

Felci defines very sporty lines, where the use of carbon can find its highest reason for use. Since Magara is convinced that the real efficiency of innovative materials and technologies exclusively lies in a project able to enhance their potential. The hulls of Ice Yachts boats are powerful, sporty and they accommodate volumes which can be adjusted according to the different customers’ needs.

“For us, customization and attention to our customers’ needs – Marco Malgara explains – is a key for interpreting the way we produce our boats. Sometimes, we have to say no and admit that ” that specific customer’s request is impracticable”. However, it’s equally important to listen to and understand. And, sometimes, there are challenges which generate innovative choices, successful ideas we can later apply to the rest of our production” .

And the production process is exactly part of this attitude towards innovations.

“To make our products custom – explains Roberto Marchesi, Production Manager and essential interlocutor between designers, technical office and workers – and work with materials like carbon, we necessarily need both artisanal processing and a certain ability to use specific materials like carbon”.

The hull is laminated with layers of quadraxial carbon fabric. It’s a meticulous processing entirely carried out by hand.

A reinforcing structural grid made of floor plates and longerons running inside the boat in both longitudinal and transverse direction is fixed to the hull making the product stronger and more rigid. This processing, too, is performed manually after precise calculations on thickness and placement of reinforcements.

It’s precisely in that stage and when systems are constructed that the combination of artisanal skills and advanced design systems finds its highest expression. Everything must be foreseen and scheduled before the manual craftsmen’s intervention

The same process is used for the deck, which is laminated in its mould. When the two parts are finished, hull and deck are assembled together and the boat is closed and put under a thermal “blanket” where, at a temperature of 60 degrees, the hull construction processing is finished with the use of epoxy resin.

Then, furniture is installed. Unlike industrial boat building processes, where each hull moves along a production line with no deck in order to be completed, Ice Yachts have a team of skilled craftsmen who enter and furnish the boat.

Joiners, installers and carpenters work together to build the “soul” of Ice Yachts boats using wooden, carbon and fiberglass elements, all resulting from the shipyard’s in-house production.

In four years, from 2012 to 2016, 19 boats were built this way. Today, 7 boats are currently under construction: a new 60-footer, which will be slightly longer than the 62-footer, three 52-foot models, a 33-foot racer and two 61-foot catamarans.

All motorboats are designed by Umberto Felci while catamarans are by Cirillo-Contreas. Next May, a new 82-footer will be built together with a 72-foot cruiser/racer.

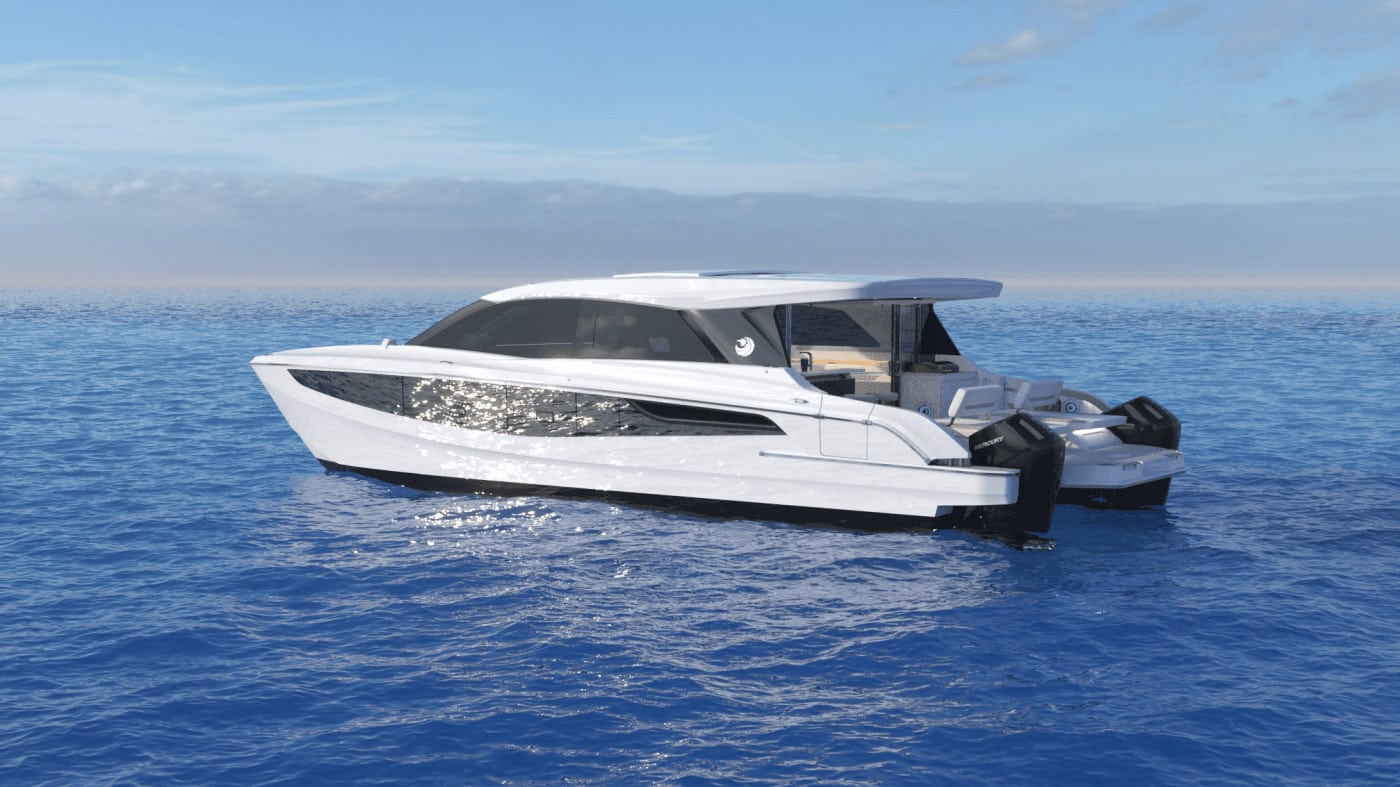

Catamarans have recently opened a new chapter. According to Ice Yachts managers, figures speak for themselves: today, they claim, 40% of boating market is made of multihulls. This is why they decided to move in this direction. A 61 and a 67-footer have already been sold and a second 61-footer have recently been commissioned.

Catamarans will even have their own production site, in an establishment currently under construction on the Po River. After all, the facility of Salvirola is not big enough to host the new catamaran.

Salvirola is a town in the province of Cremona, it’s true, but it also represents an international crossroad since Ice Yachts customers actually come from all around the world: Mexico, USA, Sweden, Germany, Hong Kong, France and many other countries.

“Of course, the era of global communication – Malgara says – helps us and many customers find our name on Internet while looking for boats with the same characteristics than ours. International boat shows, too, give a hand, even if we usually don’t join many of them. I think that the best

contribution is through the word of mouth about the quality of our products and our working style. I always try to meet customers here, show them our reality and how we build our boats. And that’s maybe the more real and more efficient marketing strategy”.

It’s a little strange to get this sea air in the midst of the valley. Maybe, it all actually started more than half a century ago in Offanengo, in the small establishment where Alpa boats were built. What is certain is that this air can be still breathed and that carbon, light materials, computers and advanced design systems used to build and develop Ice Yachts boats, haven’t repressed the passion for boats but they have enhanced it. What does matter is that Italian craftsmanship has a home, or a shed, where it can show the world what it’s capable of.