Comparative test for the three leaders of synthetic teak decking

The use of synthetic teak in marine decking is quickly and successfully replacing that of the natural wood.

There are many companies producing this material today but only three are the most popular and the most widespread ones. We therefore decided to compare the best of the current production in a no-holds-barred test.

This way, we had the opportunity to test and compare, in a very simple way, the features that most affect the choice of synthetic teak (all our staff was involved in the test and everyone was asked to express his own opinion).

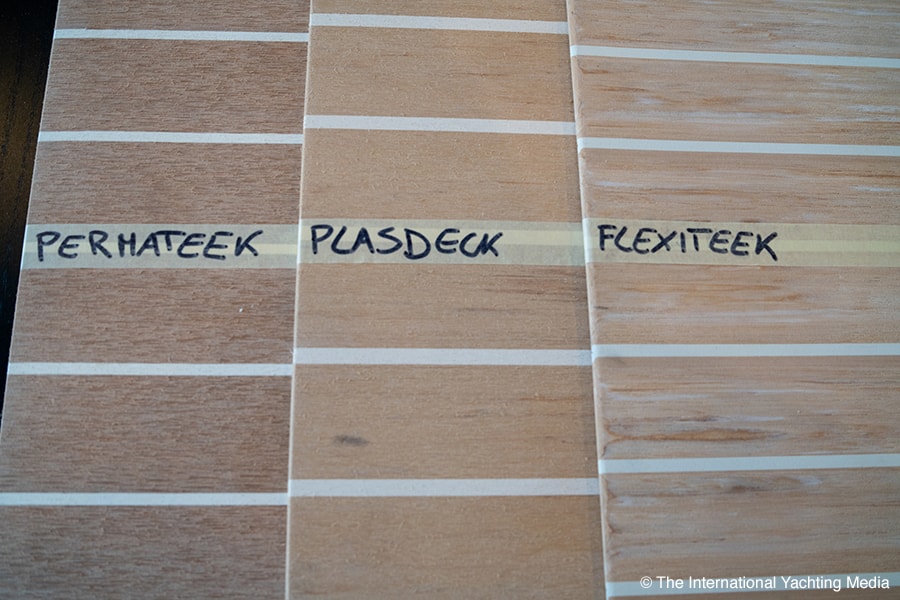

The synthetic teak we tested is, in alphabetical order, the Flexiteek, the Permateek and the Plasdeck.

Here’s what we found out:

Synthetic teak : aesthetics and touch feeling

First of all, we decided to analyze the aesthetic appearance and therefore the element that makes both boat owners and their guests fall in love at first sight.

Of course, it’s a subjective yet important choice since, once chosen, the synthetic teak has the implicit characteristic of maintening the same appearance over years.

More specifically, Flexiteek shows veins and shades that make it, in a natural way, very similar to real wood. Its colour is light biscuit.

Plasdeck, too, is

The Permateek Classic, instead, is very different from the others since its darker colour makes it more similar to aged or oil-processed wood. However, the typical nuances of wood are absent. The veins in relief, reproduced during the processing phase, are instead very marked and visible throughout the panel. But they don’t seem natural at all.

Another difference between the three products concerns the width of slats and seams. Flexiteek’s ones are narrower, slimmer and more elegant while the other two are wider.

As for the tactile sensation, we noticed that there’s a big difference between the three products. Permateek is made of harder and rougher plastic, Flexiteek is softer while Plasdeck is somewhere in between.

In our opinion, this test concludes with the following ranking: 1 Flexiteek – 2 Plasdeck – 3 Permateek

Sun exposure

After more than one hour of sun exposure, our teak synthetic panels reached the maximum temperature peak. The Permateek was the hottest one, with a temperature of 60.8 degrees, followed by the Flexiteek with a temperature of 57.3 degres and the Plasdeck with 53.5 degrees.

Yes, it’s true, the

The other two panels, instead, turned cold more quickly and, after having remained in shadow for one hour and despite the difference in their peak, they reached the same temperature of 34.8 degrees.

In addition to thermometric measurements, we also tested the sensation of warmth transmitted by the materials, walking barefoot on the different teak panels. This step resulted in a further confirmation and a surprise.

The Permateek was the hottest and the contact with the sole of our foot confirmed that. Moreover, the sensation of warmth remained on the foot for some minutes, which confirmed the excellent warmth retention capacity of the material.

Flexiteek, instead, while not registering the lowest surface temperature, when it came into a prolonged contact with our foot, proved to have the lowest warmth retention capacity. This suggests that the material composition (Flexiteek G2 patent) ensures greater heat dispersion.

In conclusion, this second test concludes with Plasdeck and Flexiteek coming joint first and Permateek in last place.

Weight

We calculated the weight of our panels on a m2 basis. This time, Flexiteek proved to be the best product. This is an important aspect to take into account when dealing with a boat. The following table shows the overall weight of teak decking on a 13-meter sailboat.

| Sample | cm | cm | cm² | m² | weight in kg | weight/m² |

covered surface

|

kg in total | |

| Flexiteek | 40 | 40.2 | 1,608 | 0.1608 | 0.721 | 4.484 | 30 | 134.515 | Flexiteek |

| Permateek | 39.5 | 40 | 1,580 | 0.158 | 0.848 | 5.367 | 30 | 161.013 | Permateek |

| Plasdeck | 41 | 41.5 | 1,701.5 | 0.17015 | 1.003 | 5.895 | 30 | 176.844 | Plasdeck |

Let’s take into consideration a sailboat, especially a performing one. A lower weight on the deck not only contributes to reduce the overall weight but also and above all reduces the weight positioned above the waterline. This way, the centre of gravity of the boat remains lower, which contributes to reduce heeling when sailing while improving performance.

This is also true for motorboats that, as you know, have wider decks and therefore need more square meters of synthetic teak. On these yachts, the main difference lies in comfort and not in performance. Especially if these boats are equipped with a flybridge: a lower weight on this means lower rolling for the yacht itself.

Ranking: 1 Flexiteek – 2 Permateek – 3 Plasdeck

Resistance to dirt

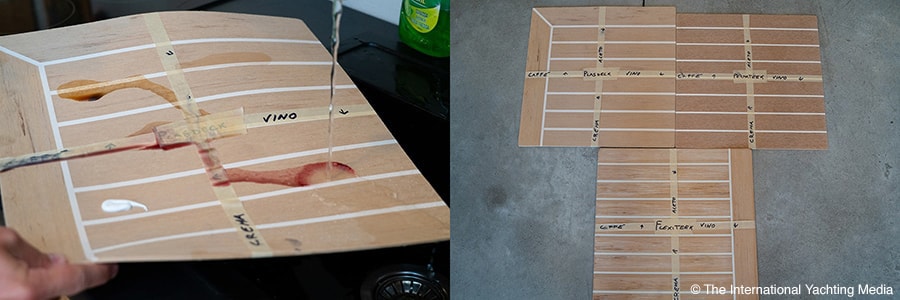

The main goal of

For the first part of our test, we spilled some staining substances and we left them on the teak surface for about one minute; then, we removed everything with what is the most used method on each boat, ie water.

The result is the same for all the three products: stains were removed with a simple cleaning carried out with the hands under the flowing water.

Damage resistance

Things changed when we tried to pierce the panels with our scissors and screwdrivers in order to simulate the most common deck accidents. This time, no sample passed the test: all of them let themselves be pierced ( the Permateek with a little bit of difficulty). This is maybe inevitable with a plastic material that, after all, is not so different from natural wood that, unlike synthetic teak, cannot be repaired if not with a long work.

Grip

In order to test grip,

To the touch, the Permateek proved to be the roughest material, capable of the best grip thanks to its more market veins.

Ranking: 1 Permateek – pari merito Flexiteek e Plasdeck

The back of panels, predisposition to gluing

Flexiteek is highly processed and shows a series of grooves (another patent of the company) that facilitate gluing without bubbles and “slipping” effects. Permateek has a micro-perforated bottom while Plasdeck is the smoothest one.

For obvious reasons of simplicity and installation quality, this chapter concludes with this final ranking: 1 Flexiteek – 2 Permateek – 3 Plasdeck

Conclusions

Rankings speak for themselves and, even if individual differences are not big, Flexiteek is undoubtedly the absolute winner.

It proved to be multi-purpose, highly efficient in all respects and even the most similar one to natural wood.

However, it is also true that boat owners, or better their personal tastes, have the final say. These synthetic teak panels are offered for sale in many colour options, so you can choose the colour combination you like the most or that best matches your boat.

We thank all three manufacturers that, as proof of their good faith, accepted the test without hesitation.

Below you will find their contact details.

Flexiteek

Via guidetti 45, 40052 Passo Segni (BO)

Phone: +39 338 3422028

Permateek

Via Foscolo 8, 34131 Trieste

Phone: +39 040 2453942

Plasdeck

Via Graz 12, 38121 Trento

Phone: +39 366 4078168

15 Responses

Thanks for this article, very interesting!

any chance to add to the test a piece of real teak?

Also, quite important, particularly on racing boats, the abrasion test. Ropes and sailbags dragged on the foredeck could leave marks…

thank you

As a certified synthetic teak installer that has installed all three products and watched them weather over several years, Permateek looks newer longer. It is slightly heavier and stiffer but goes down straighter.

Flexiteek is challenging to keep the lines straight upon installation.

I have found the 2G has a tendency to mold on the surface where the others do not.

The grooved back of Flexiteek is only good on paper! When installed over aggressive non-skid, the grooved back may allow for water penetration. This can damage the gel coat and allow moisture to enter the coring.

Your test only showed the appearance and

Temperature concerns while there are many aspects to consider.

If Permateek submitted a similar color to the others, the temperature difference is insignificant.

All surfaces are sanded when manufactured. And again when fabricated.

The texture can be anything from smooth to “hairy”.

Don

DRB Marine

USA

DRB Marine used to dabble in Flexiteek before switching over to Dek-King, which had excellent feedback all over the US and beyond. They have now been acquired by Flexiteek, which is a compliment on the standard of quality manufacturing performed at their U.K. location.

Indeed, Flexiteek is now produced fully at this factory with glowing success!

As my Company handles the Importing for the Americas, let’s remember that DRB chose ‘not’ to go with an existing factory that had worked well for the last three years, and continues to increase the quality control levels in order to maintain the #1 status.

Don produces excellent work, just a shame he chose to jump ship for reasons not related to the quality!

Hi. I am in search for a synthetic deck manufacturer who has already templates for FP Lavezzi 40… Please email me at ron.gritz@gmail.com if you happen to know one. Thank you!

Hi. I am in search for a synthetic deck manufacturer who already has templates for the Leopard 50… Please email me at kevindeanferreira@gmail.com if you happen to know one. Thank you!

Hi I am in search for a synthetic teak deck manufacturer that has templates for Princess 92 55′ with Flybridge.

Thank you

I am looking for a template for my 37 ft 1989 Pearson Sail boat

Template for a 78 ft Choey Lee motorsailor?

I would not use Permateek. I had a bad experience on my 66 foot boat. The Permateek was installed by Permateek. The deck developed hundreds of blisters. It has been 6 months and Permateek has not done anything except write emails trying to figure out a way to not honor thier warranty. The product is not as represented. The installers are not qualified. They do not honor their warranty. So far I am out $22,000.

Just an update, there were issues with this boat as we attempted to cover the decking surface which was not fibreglass in the hope that the underdeck was not porous. Unfortunately, this was not successful and blisters did occur. As a company, we always honour our warranty and having made extensive investigation into what went wrong, we assess that fitting synthetic decking over this surface was not going to work out. As a result, Mr Tomlinson was fully refunded.

As a company, we have fitted thousands of decks without issue and we are very proud of the work we carry out.

You missed one main thing. Leave some dirt or whatever on flexiteek for 5-6 hours and then try to wash it, you will be suprised. Flexiteek will alow dirt to go all the way down and you cant remove that or sand it out but with permateek and pladeck is different story. Flexiteek is on the last place just because of that sucking failure. I know what I talking about because I was working with flexiteek and permateek.

The author of the article forgot another major brand: xxxxx that is sold …..

HI Denis, it was a pleasure to read your comment, unfortunately I had to remove the brand and the rest of the text becacuse it was ADV.

Your product was not included in the test because probably at the time of the test it either did not yet exist or was too “young” to be considered.

However, we are more than willing to include your product in the article if of course you are able to send us a sample of the product. The other manufacturers at the time sent us a sample of about 40 centimeters per side, as you can see from the pictures.

The sample will then be examined, measured, weighed, exposed to the sun to measure surface temperature, dirtied and washed, in the same manner as we did with the others and the results, since we are no longer in possession of the old samples, will be displayed at the end of the article.

Just send an email with your contact details and we’ll organize.

Best regards

Luca

We are also a supplier of pvc material in UK. Since the material can be sanded any of the 3 could come top of this grouping depending on which material was sanded the coarser. The materials are similiar with the best quality beng 100% virgin pvc. This applies across most reputable brands except one that has some additives that reduces weight and makes the welds less durable and apparently more susceptible to staining.

Hello, if possible, we would like to know if they will last for years and in average experience, how many?

Pictures actually installed on boats from one to as many years as possible would be appreciated.

Thanks in advance.